Products specificatrion

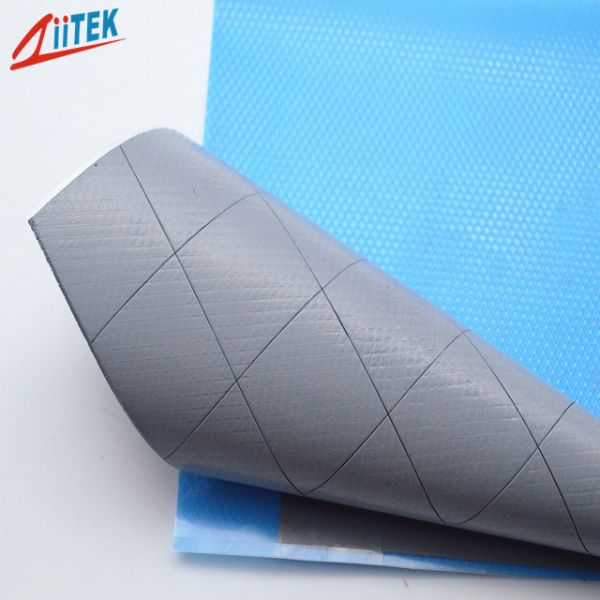

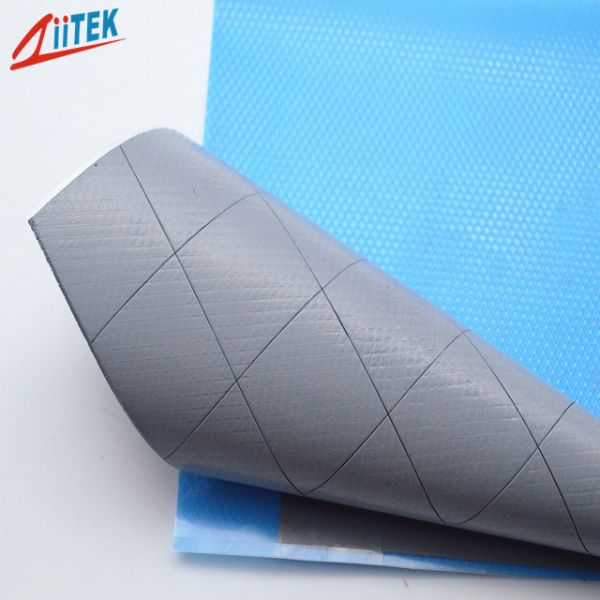

Product Thicknesses: 0.020-inch to 0.200-inch (0.5mm to 5.0mm) with increments of 0.01

inch (0.25 mm).

Product Sizes: 8" x 16"(203mm x406mm)

Component Codes:

Reinforcement Fabric: FG (Fiberglass).

Coating Options: NS1 (Non-adhesive treatment), DC1 (Single-sided

hardening).

Adhesive Options: A1/A2 (Single-sided / Double-sided adhesive).

The TIF series is available in custom shapes and various forms. For

other thicknesses or more information, please contact us.

Packaging Details & Lead time

The packaging of thermal pad

1.with PET film or foam-for protection

2. use Paper Card To Separate Each Layer

3. export carton inside and outside

4. meet with customers' requirement-customized

Lead Time :Quantity(Pieces):5000

Est. Time(days): To be negotiated

Ziitek Culture

Quality :

Do it right the first time, total quality control

Effectiveness:

Work precisely and thoroughly for effectiveness

Service:

Quick response, On time delivery and Excellent service

Team work:

Complete teamwork, including sales team, Marketing team,

engineering team, R&D team, Manufacturing team, logistics team.

All is for supporting and servicing a satisfy service for

customers.

FAQ:

Q: Are you trading company or manufacturer ?

A: We are manufacturer in China.

Q: What's the thermal conductivity test method given on the data

sheet ?

A: All the data in the sheet are actual tested.Hot Disk and ASTM

D5470 are utilized to test the thermal conductivity.

Q: How to find a right thermal conductivity for my applications

A: It depends on the watts of power source , ability of heat

dissipation. Please tell us your detailed applications and the

power, so we can recommend most suitable thermal conductive

materials.